CONTEXT:

NATURALLY OR CHEMICALLY

AGGRESSIVE ENVIRONMENTS

MOST COMMON CHALLENGES

FOR METAL ROOFING .

- Inefficient protective coatings:

the decay of the protective coating can activate early corrosion of the metal substrate .

- Specific critical areas:

corners of bends - due to the stretching or permeability of the paint coating – edges, fastening holes, scratches and cuts.

The Ondulit advantage

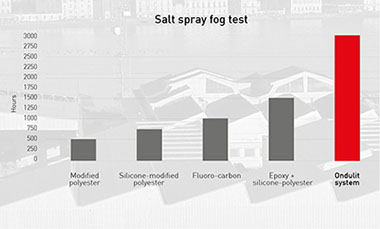

Up to 0.07” thick (1700 micron, compared to common 25 microns of standard coatings), our protective plastic bituminous compound totally shields the steel substrate, making our panels resistant to corrosion and assuring a virtually unlimited protection even in the harshest environmental conditions.

Aluminum foil protects the anticorrosive layers keeping its plasticity over time.

Neither application in coastal or inland areas subject to sea winds – with high levels of humidity and heavy concentration of salt – nor application in industrial and urban areas - highly polluted by different chemical compounds – will ever be a problem when choosing an Ondulit panel for your roof (3,000 hours exposure time, salt spray fog test per UNI EN ISO 9227 and 45 exposition cycles, sulphur dioxide test per UNI EN ISO 6988).

DESIGNED &

MANUFACTURED IN ITALY

SINCE 1953